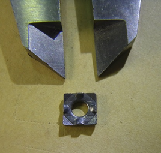

The dimension of washer is 6 mm. If ƒÓ3mm hole deviates, such part shall be selected as defect.

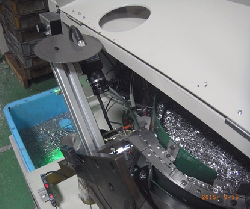

Further more to provide some automation devices for,

(1) Dimension defect determination sorting

(2) Auto count of quantity of small parts after progressive stamp progress.

(2) Both by using "Image Processing Thecnology"

(3) Assembly with other part(plastic and non-ferrouss metal part) by using

servo system

(3) Those device & equipment is designed and assembled in our parent company.

There are 3 items of our company strenghts.

Tighten 14 screws -> Conduction-withstand voltage test -> Dimension check opening of the terminal in thesocket -> screw floating check -> tipping check -> Label pasting of OK part -> stamping Passed mark

using Image Processing unit

The openess of terminal inside of socket is checked.

OK part is delivered OK box after stamping OK stamp

| We have lot of experiances of next process after press stamping for small parts and we can design usefull equipments in utilizing its experiance and our technology. Please don't hesitate to contact to us. |

Square washer Hole positiondeviation Image processing device

Mini control socket (bakelite) Conduction-withstand voltage test devise

Strength (3) : Automation devices

Automatic screw tightening device

for small metal parts after press stamping